GI perforated sheets have become a crucial material in various industries due to their combination of strength, durability, and design flexibility. These sheets, crafted by punching precise hole patterns into galvanized iron (GI), offer a wide range of applications, from architectural facades to industrial filters. The versatility of perforated sheet metal lies in its customisable hole patterns, each serving specific purposes and providing unique advantages.

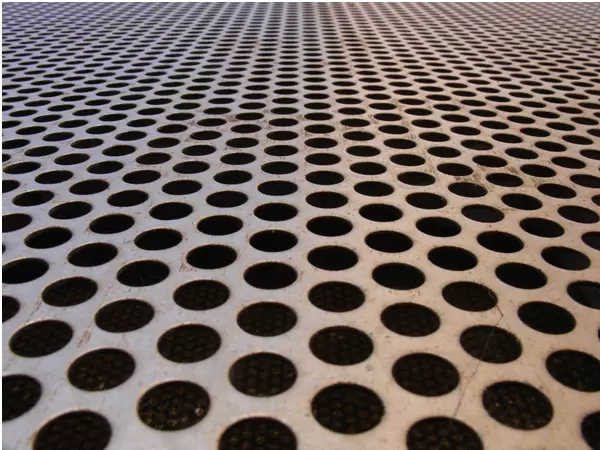

Round Hole Pattern

The round hole pattern is one of the most common and widely used designs in GI perforated sheets. Its simplicity and uniformity make it suitable for numerous applications, including ventilation, filtration, and decoration. Round holes allow for optimal airflow and light transmission, making them ideal for HVAC systems, acoustic panels, and sunshades. The even distribution of holes also contributes to the structural integrity of the sheet, making it durable and reliable for both industrial and architectural purposes.

Square Hole Pattern

Square hole patterns are another popular choice in perforated sheet metal. These patterns are often preferred for their clean and modern appearance, making them suitable for aesthetic applications like interior design and building facades. Functionally, square holes provide excellent open area percentages, which enhance their effectiveness in screening and sieving processes. They are often used in equipment guards, partitions, and decorative panels where strength and visual appeal are equally important.

Slotted Hole Pattern

The slotted hole pattern, characterised by elongated holes, offers unique advantages in applications requiring directional flow or drainage. Commonly used in industries such as agriculture and construction, GI perforated sheets with slotted holes are ideal for grain drying systems, drainage systems, and conveyor belts. The elongated shape allows for better debris removal and fluid movement, while the galvanized coating ensures resistance to corrosion in harsh environments.

Hexagonal Hole Pattern

Hexagonal hole patterns are chosen for applications demanding maximum open area without compromising strength. The honeycomb-like structure not only provides an appealing design but also enhances airflow, making it suitable for ventilation systems, speaker grills, and lighting fixtures. Hexagonal holes in GI perforated sheets are also favoured in industries requiring lightweight materials with high efficiency, such as automotive and aerospace sectors.

Custom Hole Patterns

For specialised applications, custom hole patterns in perforated sheet metal can be designed to meet specific requirements. These patterns allow for greater creativity in architectural projects, enabling intricate designs and tailored functionalities. Custom perforations are often used in signage, branding, and artistic installations, where unique aesthetics and precise specifications are essential.

Applications Based on Hole Patterns

The choice of hole pattern in a GI perforated sheet depends on its intended application.

- Industrial Use: Round and slotted holes are common in filtration, screening, and sieving processes.

- Architectural Design: Square and hexagonal patterns are popular for facades, ceilings, and decorative elements.

- Acoustic Panels: Round and hexagonal holes enhance sound absorption and noise control.

- Agriculture: Slotted patterns aid in grain drying and ventilation systems.

Each hole pattern brings specific advantages, allowing GI perforated sheets to adapt to diverse needs while maintaining their durability and functionality.

Conclusion

The variety of hole patterns available in GI perforated sheets highlights their versatility across industries and applications. From round holes for optimal airflow to hexagonal designs for lightweight strength, these patterns cater to both practical and aesthetic needs.

Dinco Trading LLC plays a significant role in supplying high-quality perforated sheet metal, ensuring that industries and architects alike have access to materials that meet their specifications with precision and reliability.